When purchasing industrial aluminum profiles, the following are some key indicators to pay attention to:

1. Material and alloy composition

Clear the alloy number of aluminum profile, different alloy composition determines its strength, hardness, corrosion resistance and other properties. For example, 6063 alloy is widely used in industrial fields, with good processing properties and moderate strength; 7075 alloy has a higher strength, but the processing is relatively difficult.

Pay attention to the impurity content in the alloy, low impurity content can improve the quality and performance stability of aluminum profiles.

Second, dimensional accuracy

Check whether the length, width, thickness and other dimensions of the aluminum profile meet the design requirements. Excessive dimensional deviation will affect the assembly accuracy and structural stability.

Pay attention to shape accuracy indexes such as straightness, flatness and twist degree of profiles. These indicators are important to ensure the structural regularity and appearance quality of aluminum profiles after assembly.

Third, surface quality

Observe whether the surface of the aluminum profile is smooth and flat, and there are no scratches, bubbles, pitting and other defects. Good surface quality is not only beautiful, but also improves corrosion resistance and coating adhesion.

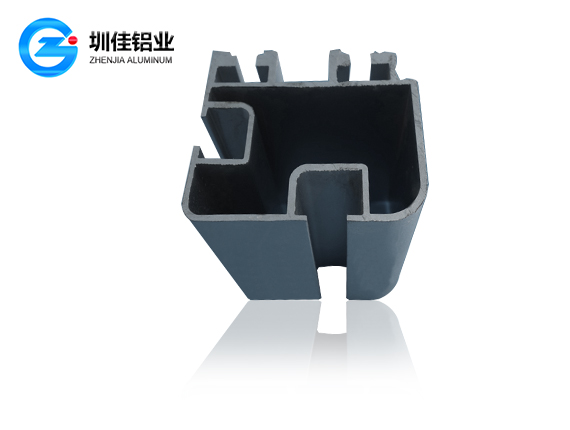

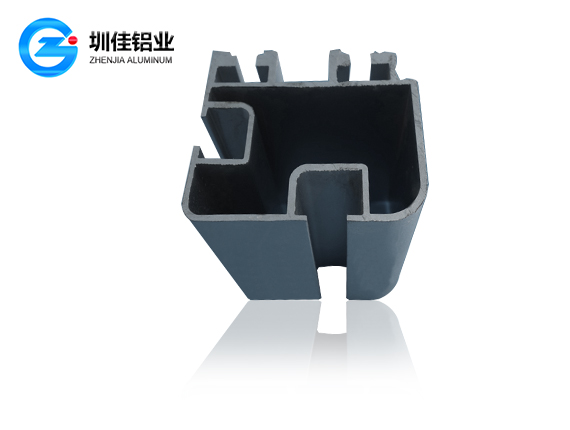

Industrial aluminum profile

Check the quality of the surface treatment, such as anodizing, electrophoretic coating, powder spraying, etc. The surface treatment should be uniform and firm, with good corrosion resistance and wear resistance.

4. Mechanical properties

Understand the strength, hardness, toughness and other mechanical properties of aluminum profiles. These indicators determine the ability and reliability of aluminum profiles under load. You can understand the mechanical properties of the product by looking at the material report or performing mechanical properties tests.

For some special applications, such as the need to withstand dynamic load or impact, it is also necessary to pay attention to the fatigue strength and impact toughness of aluminum profiles.

5. Machinability

Consider the machinability of aluminum profiles, including the difficulty of cutting, drilling, tapping, bending and other processing. Good machinability can improve the processing cost and production efficiency.

To understand the welding performance of aluminum profiles, for the structure that needs to be welded and assembled, aluminum profiles with good welding performance should be selected.

Price and cost

Compare the prices of different suppliers, pay attention to whether the price is reasonable, to avoid too low prices may mean quality problems.

Considering the procurement cost is not only the unit price of aluminum profiles, but also includes transportation costs, processing costs, after-sales service and other factors. Comprehensive consideration of cost factors, choose cost-effective products.