The method based on infrared imaging technology can be used for rapid detection of internal cavity strain of industrial aluminum profiles. The following are the detailed detection steps and the advantages of this method:

Detection procedure

Prepare the equipment:

Use an infrared camera and its accompanying software. Ensure that the camera Settings are correct, including selecting the appropriate magnification, setting the camera scan area and contrast parameters.

Place the sample to be tested:

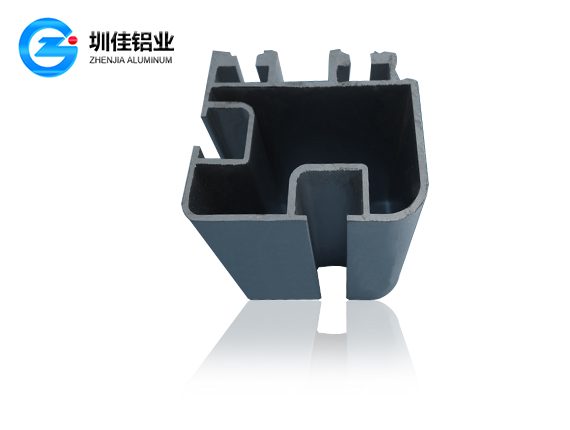

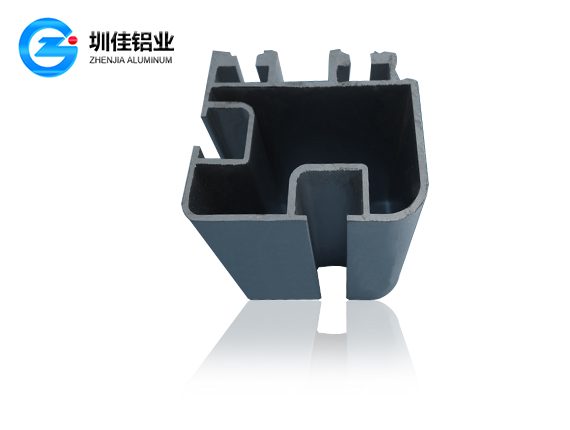

The industrial aluminum profile to be detected is placed in the scanning area of the infrared camera to ensure that the inner cavity can be clearly photographed by the camera.

Take an image:

An infrared camera was used to photograph the aluminum profile and obtain the infrared distribution image of its inner cavity.

Image analysis:

The images obtained were analyzed by the software. By marking the infrared distribution of the inner cavity of industrial aluminum profiles, the strain of the inner cavity can be clearly observed.

Judgment conclusion:

According to the results of image analysis, whether there is strain in the inner cavity of industrial aluminum profiles is judged, and the corresponding conclusions are drawn.

Method advantage

Rapidity:

The whole detection process only takes a few minutes, which greatly improves the detection efficiency.

Accuracy:

The high resolution infrared camera can clearly display the strain situation in the cavity of the industrial aluminum profile, and the judgment result is accurate and reliable.

Non-destructive:

The detection method is based on infrared imaging technology, which does not need to destroy industrial aluminum profiles and ensures the integrity of samples.

Automation:

With the analysis software, the test results are not only accurate and reliable, but also can automatically output reports, further improving work efficiency.