To ensure that the quality and performance of industrial aluminum profiles meet the standards, it is necessary to control them from the following aspects:

Raw material quality control: The quality control of aluminum profiles begins with raw materials. Qualified raw materials are the basis to ensure the quality of aluminum profiles. The selection and procurement of aluminum alloys require strict control, including supplier qualification, production process, quality management system evaluation and audit. At the same time, raw materials need to be inspected in terms of chemical composition and physical properties to ensure compliance with relevant standards

Production process control: In the production process of aluminum profiles, the process control of each link is important, including melting and casting, drawing and extrusion. It is necessary to control the melting temperature, melting time, the use of melting agents and other parameters to ensure that the composition of aluminum alloy is uniform and pure. During the casting process, parameters such as casting temperature, mold temperature and cooling speed are controlled to ensure the normal solidification process of aluminum profiles and avoid defects

Statistical process control (SPC) : Statistical process control is applied in the production process of industrial aluminum profiles, and each production control point is divided into quality control points and process control points. The stability of the production process is evaluated by the control chart, and the satisfaction degree of the production process to various quality requirements is judged by the process ability index. The data acquisition system based on computer network is established to ensure the timeliness of data, the visual production log system is used to facilitate the tracking of quality problems, and the standard SPC implementation process is formulated

The production process of industrial aluminum profiles mainly includes the following steps:

Aluminum ingot preparation:

Aluminum ingot selection: Choose the right aluminum alloy material, commonly used aluminum alloy 6061, 6063, 7075 and so on

Aluminum ingot smelting: The aluminum ingot is placed in the furnace to heat the melting point, so that it becomes a liquid aluminum alloy

Squeeze:

Die design: The extrusion die is designed according to the section of the desired profile, and the die is usually made of high-strength alloy steel

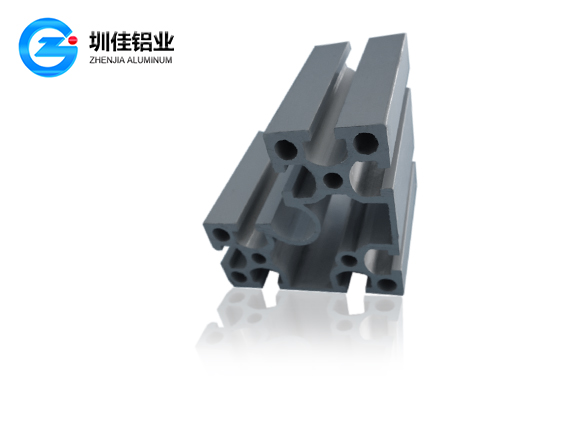

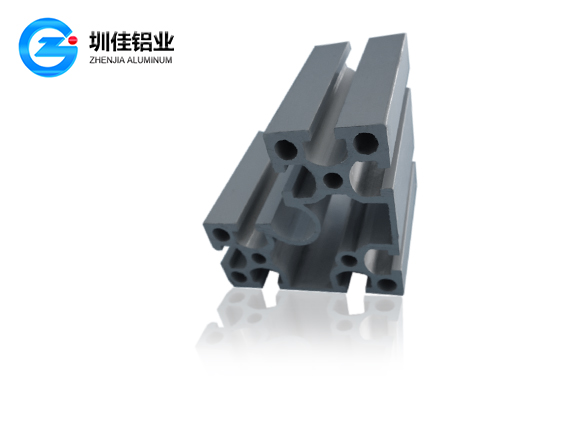

Extrusion process: The heated aluminum ingot is placed in an extruder, through which the aluminum alloy is extruded through the mold to form the profile with the required cross-section shape

Cooling: The extruded aluminum profiles are cooled by water or air cooling

Heat treatment:

Quenching: Through rapid cooling (such as water quenching, wind quenching), improve the strength and hardness of aluminum alloy

Aging treatment: The quenched profile is aged and maintained at a certain temperature for a period of time to achieve the mechanical properties of the material

Surface treatment:

Oxidation treatment: A dense oxide film is formed on the surface of the profile by electrolytic method to improve corrosion resistance and surface hardness, and can be dyed

Coating: including powder spraying and electrophoretic coating, through these methods, the coating is uniformly attached to the surface of the profile to form an anti-corrosion coating

Follow-up processing:

Machining: According to the specific application requirements, cutting, drilling, tapping, milling and other mechanical processing

Assembly: The processed aluminum profiles are assembled, such as assembled into frames, brackets and other finished structures

Inspection: Inspect the size, surface quality and mechanical properties of the finished product to ensure that it meets the design requirements and quality standards

Packaging and Storage:

Packaging: According to customer requirements and transportation conditions, the aluminum profile is properly packaged, usually using plastic film, cardboard or wooden box for protective packaging

Storage: Store in a dry, ventilated warehouse to avoid moisture, collision and chemical corrosion

Quality management system: Establish and implement ISO9000 family and other general quality management system, through quality planning, quality control, quality assurance and quality improvement activities to achieve quality policies and objectives

PDCA cycle: Follow the PDCA (plan-do-Check-act) cycle, constantly carry out quality improvement activities, and enhance the competitiveness of aluminum products

On-site quality management: including the whole process quality control, production factors control, quality information feedback control and nonconforming product control. The whole process quality control is to control the quality of the entire production process of aluminum profiles, the control of production factors is to control all factors affecting the quality of aluminum profiles, and the quality information feedback control is to realize the rapid and effective transmission and timely processing of quality information. The control of nonconforming products is that the aluminum profiles determined to be nonconforming products after inspection and test must be well marked, recorded, evaluated, isolated, processed and notified

Heat treatment control: The heat treatment of aluminum profiles is an important process to improve its strength and hardness. During the heat treatment process, parameters such as temperature and time need to be controlled to ensure the ideal mechanical properties of aluminum profiles

Surface treatment control: The surface treatment of aluminum profiles can improve its corrosion resistance and decoration. Common surface treatment methods include anodizing, spraying and electrophoretic coating. In the surface treatment process, it is necessary to control the composition of the treatment liquid and treatment time and other parameters to ensure the quality of the aluminum surface